Best Epoxy for Plastic – Find the strongest Epoxy for Plastic

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

There are all kinds of different glue and adhesive options out there. These include adhesives for DIY and crafting projects, as well as industrial-strength adhesives for manufacturing. If you are a hobbyist, you will use glue for all kinds of projects and applications. It can also be used for doing other tasks, such as plastic modeling. When choosing the best epoxy for plastic, you will need to be aware of what the adhesive is designed for. Not all glues are suitable for use on plastic – each one has its own unique formulation. Some are versatile and some offer very limited uses. Let’s explore some of the best plastic epoxy options below, and what you should look out for in this type of product.

Table of Contents

The Two Main Adhesive Types

There are all kinds of different adhesives out there with different bonding strengths and applications. Some have a relatively low cohesive strength while others form a super-strong bond. Some are heat resistant, some are flexible, some are water-resistant, and so on. Within the wide range of adhesives available, there are two main umbrella categories:

- Reactive adhesives

- Non-reactive adhesives

Epoxy for plastic is considered a reactive adhesive. This is because a chemical reaction is required between two separate elements in order to form an adhesive that can harden and cure. An adhesive like super glue is also considered reactive, except that this is a one-part glue that reacts to the environmental conditions. Regular white craft glue is a non-reactive adhesive. When choosing glues and adhesives, it is important to consider the materials and surfaces that you will be sticking together. Here is a quick reference point for some common examples:

- Epoxy for plastic, rubber, fiberglass, metal, and glass

- Acrylic for metal, plastic, rubber, glass, and fiberglass

- Cyanoacrylates for plastic, fabric, leather, and metal

- Urethane for plastic and various other surfaces

There are many different adhesives available that work with plastic. However, you will need to find the one that reacts best with your specific plastic repair and project. Using the best epoxy for plastic offers a more durable and resistant adhesive option. Not only does epoxy form a powerful bond, but it can also be temperature resistant, UV resistant, solvent resistant, and able to withstand strong force.

Why Use Epoxy for Plastic

Having the best epoxy for plastic available around the home is always a good idea as it can be needed for repair jobs and quick fixes all the time. Using epoxy for plastic provides an easy solution for many repair jobs, although it also has its downsides.

PROS

- Suitable for use on a wide range of materials and plastics

- Has a high level of durability and strength

- Heat resistant and can handle strong mechanical forces

- Chemical resistant

- Waterproof epoxy for plastic is available

- It has a good shelf life

- Various accelerators and additives can be combined into it

CONS

- It requires mixing two parts together, so you will need some knowledge and precision mixing and understanding the ratios

- This kind of adhesive can be more expensive

- One opened, the pot life can be limited

- Some epoxy adhesives can be harmful, so safety precautions are necessary

The Best Epoxy for Plastic

If you need to bond plastics, then you will need to find the best epoxy for plastic. But which one to choose with all the products available? We have chosen some of the top plastic epoxy picks below.

Strongest Bonding Plastic Epoxy: JB WELD Plastic Weld

If you are after an adhesive to form a superior strong bond with plastic, then be sure to check out this adhesive by JB Weld. This is our pick for the strongest epoxy for plastic that can be used over a wide range of applications. This adhesive is good for use on water tanks, PVC pipes, plumbing projects, and all kinds of other jobs. However, the glue does not bond to every plastic type – such as polyethylene. Just be sure you know what type of plastic you will be working with before purchasing the epoxy.

- J-B Weld is formulated to repair and rebuild various plastic compounds and surfaces

- It takes 25 minutes to set and cures in 3 hours

- PlasticWeld can withstand continuous temperatures up to 250 Fahrenheit

This epoxy adhesive comes in two parts, and needs to be mixed manually. The two parts of the putty need to be mixed together until you reach the perfect thickness and texture. Then you simply apply it to the plastic surface and will have around half an hour before the adhesive cures. This strongest epoxy for plastic takes roughly three hours to fully cure. It has a whitish appearance when dried. This incredibly strong epoxy bond can withstand high temperatures. It is also easy to shape and mold as it is a putty, and it can be sanded down, cut, or drilled when cured.

PROS

- Forms a seriously strong bond

- Has a relatively short curing time

- Keeps a bit of flexibility when cured

- The epoxy doesn’t shrink when drying

CONS

- Has quite a strong odor

Whether you require an adhesive for a small DIY job at home or a large scale industrial project, this is one of the best plastic epoxy options available. You get a seriously powerful, heavy-duty bond suitable for a range of scenarios and plastic applications.

Value for Money: PC-CLEAR Epoxy Adhesive

PC-Clear offers a super useful product that won’t break the bank. This is one of the best epoxy for plastic options, but it can also work really well with wood, ceramics, glass, concrete, metal, and fabric. Another benefit of this adhesive is that it dries without leaving any traces, so it can be used effectively over detailed areas. This is a very strong epoxy that can withstand tough environmental conditions. For convenient use, this epoxy for plastic comes in a liquid form with double syringes. Once applied and mixed together, the epoxy will start to cure after about four minutes. This means that you will have to work fast. When dry, you get an effective bond that has a clear finish. The epoxy should be left for about 24 hours before it cures completely.

- It turns opaque initially then clear to full cure to blend in with bonded material

- Continuous service temperature range from -20 to +200 degrees F

- Provides work time of 4 minutes, cure time for function of 1 hour, full cure time of 24 hours

PROS

- Highly temperature resistant

- A very durable and tough adhesive

- Works well with all kinds of different surfaces and materials

- Offers excellent value for money

CONS

- Has a 24 hour full cure time

If you are after the best epoxy for plastic in terms of value, then this product would be a great choice. The epoxy is of very high quality, while still offering an affordable price tag.

Overall Best: GORILLA 2-Part Epoxy

There are many great plastic epoxy options available, but this one by Gorilla has to be considered the overall best epoxy for plastic. This is thanks to its versatility, superior bonding strength, and clean clear finish. The epoxy is a good choice for various plastics, but it can also be used on a wider range of other surfaces, such as glass, tiles, wood, metal, and ceramics. This is also a waterproof epoxy for plastic, and it will be able to withstand solvents. It can be used for all kinds of repair jobs, as well as heavy-duty bonding and filling in gaps. This adhesive is packed in a syringe form with a separation between the hardener and the epoxy. When applied, an equal amount of both parts are released for easy mixing.

- Strong, permanent, fast and gap-filling; Great for multiple surface applications

- Best for tough repairs requiring a durable bond, gap-filling and solvent resistance

- Dries Clear; 5 Minute curing time with easy-to-Use Syringe

PROS

- Good value for money

- An excellent waterproof epoxy for plastic

- Solvent resistant

- Offers a superior strength bond

- Suitable for a wide range of materials

CONS

- Can only be used once when bought

This epoxy for plastic offers a fantastic all-around solution. You get a quality bond, a high level of durability, a clear drying finish. This epoxy adhesive is also very versatile and easy to apply.

Most User-Friendly Plastic Epoxy: YANYI Epoxy Putty Stick

Keeping a convenient plastic epoxy around the house is always a good idea for any DIY project that may pop up. This epoxy putty by Yanyi offers a seriously easy solution for anyone wanting to quickly create a strong bond. This plastic epoxy forms a putty that can be easily shaped to suit any application. Thanks to the putty format, this epoxy can also repair leaks and seal pipes, pools, and any other similar surfaces. All you need to do is cut and work the putty until it forms the right even color anmd consistency. Bond the surfaces with your putty and leave it to cure. The total working time will be around ten minutes to work with the putty. It will harden in an hour, and fully cure after 24 hours.

- Bonds to metal, wood, glass, ceramic, fiberglass, stone, marble and many rigid plastics

- Easy to use: Simply cut, hand knead and let it dry

- After 24 hours: completely hardened and permanently fixed

PROS

- Very easy to mix and use

- The putty creates a very strong and durable finish

- Suitable for a wide range of applications

CONS

- This adhesive has a very strong odor when in use

Anyone after an easy to use putty for quick fixes and DIY projects around the house will love this product. It is easy to use, easy to mix, and still forms a superior strong bond.

Guide to Using the Best Epoxy for Plastic

Before you start working with the best plastic epoxy you will need to make sure that everything is prepared and ready. Once the epoxy is mixed together, you will have a limited working time. For this reason, you will need to make sure that you are completely ready to go. Get the workspace neat and clean, and clear away anything you dont want the adhesive to land up on. The air temperature and humidity also play a role in the curing of the plastic epoxy, so pay attention to this. Ideally, you want to work in an environment of around 75 degrees Fahrenheit without any humidity. The work area needs to be well ventilated with plenty of airflow. this is because the epoxy can release strong fumes. If you are not careful about inhaling these fumes, they could pose a health risk. These types of epoxy adhesives are often highly flammable as well. Below are some useful steps and tricks when using epoxy for plastic.

- First, always check any instructions on the products label to understand the product-specific requirements. Doing this will also allow you to make sure that you have the correct adhesive for your application.

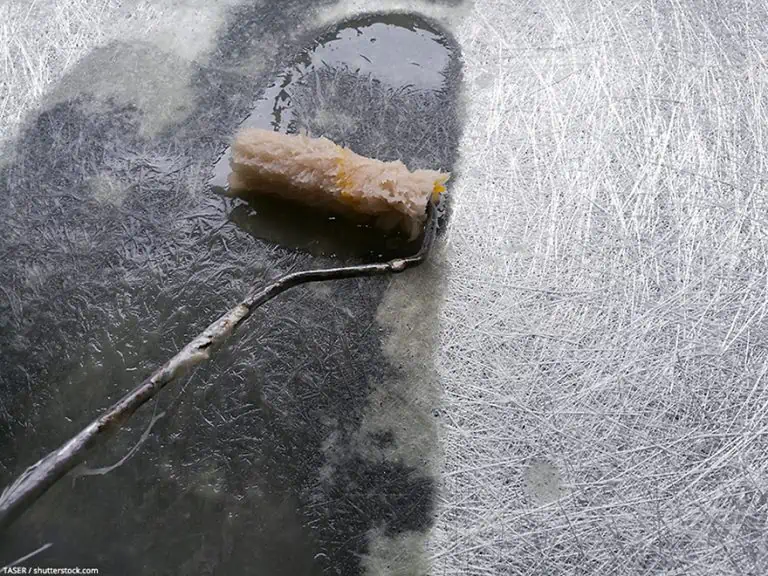

- Sand the surface first to get it slightly coarse. This will help with adhesion

- Wipe away any dust or dirt so that you are working with a clean and dry surface

- If using a syringe dispenser, hold up the syringe and cut off the tip

- Press up the syringe and remove any bubbles

- Make sure that you have a paper plate or disposable surface ready

- When you are ready to bond the surfaces, press down on the syringe to release the adhesive. The two parts will mix together as they release – creating a perfectly evenly mixed ratio

- When you have released enough epoxy, replace the cap and wipe the tip clean

- Spend some time mixing together the resin and hardener so that you have a well-mixed, even consistency

- Add this adhesive to your surface and bond the two items together. Press them together firmly to create a bond

- Know what the setting time is and how long the adhesive will take to cure. This varies between products. The information on this should be available on the label

Another variant to this kind of adhesive is a putty epoxy. These involve taking the two different putty elements and mixing them together like dough. The putty can then be applied as a filler and an adhesive. You can use a blade or knife to get rid of any excess putty.

Removing Plastic Epoxy

The best epoxy plastic is formulated to be strong and long-lasting. This means that removing the stuff is not very easy at all. Once cured, the epoxy adhesive can be incredibly difficult to remove. Making sure that your workspace is clean and free of anything you dont want coming into contact with the epoxy is important. Removing hardened epoxy is a challenge, but it is still possible. Use an adhesive remover to start breaking down and softening the cured adhesive. Paint thinners or denatured alcohol can work well here. Do this by wiping the area with a cloth coated in your chosen substance. Doing this should be able to remove the epoxy without leaving behind traces and residue. Just be careful when handling these substances, and work in a well-ventilated space. Wearing gloves is recommended.

Softening the epoxy makes it easy to remove. Rubbing the area with a cloth and acetone should help to get the area wiped off clean. If the epoxy comes into contact with your skin, quickly wipe it off with some vinegar. If you wear gloves that you keep slightly wet, the epoxy is easier to work with.

Epoxy for Plastic Safety Considerations

When using the best plastic epoxy, there are a number of safety considerations and procedures that you should follow.

- Wear gloves to avoid any contact with your skin. Try to also work in a long-sleeved shirt to add better protection for your skin.

- It’s also a good idea to wear protective goggles when working with epoxy adhesives

- Always try to work somewhere with good airflow and ventilation. If the epoxy has a strong odor or powerful fumes, then consider wearing a mask

- If any of the epoxy ends up in your eye, wash the eye out with water and go to a doctor

Frequently Asked Questions

How Long Does a Two-Part Epoxy Adhesive Take to Dry?

There are many different factors for this, including the specific brand and product, the environmental temperature, and air flow. Usually, epoxy adhesives require 24 hours to cure completely.

How Do You Mix Plastic Epoxy Adhesives?

Mixing an epoxy adhesive needs to be done with precision. Some products are available in syringes that are already mixed and portioned out. This makes it easy to get the right ratio. You also get putty adhesives that need to be mixed together as if they were dough.

Is Epoxy for Plastic an Effective Product?

Epoxy adhesives are a brilliant choice for bonding plastics. They work well with a wide range of plastics and offer a super-strong bond while still providing some flexibility. Not all epoxy adhesives work with the same plastics, so just be sure to check this out.

Can You Get Waterproof Epoxy for Plastic?

Epoxy adhesives have many different qualities, including heat resistance and chemical resistance. And yes, there are also waterproof epoxy options for using on leaks, pools, and plumbing solutions.

How Much Epoxy Adhesive Do You Need?

This depends completely on your needs and the specific application that you are doing. Some adhesives come in a pack that can only be used once as it all mixes together, others provide multiple uses. Be sure to figure out just how much epoxy adhesive you require before you buy it.

Will Additional Hardener Make the Epoxy More Durable?

Epoxy adhesives need to be mixed to a specific ratio otherwise they won’t work. Adding more hardeners won’t increase durability or strength. There is only one level of durability that each epoxy resin can cure at.

Finding the best epoxy for plastic offers a brilliant solution for bonding all kinds of jobs. Make sure that you are ready and fully prepared, and you will be able to create easy, long-lasting bonds with this durable type of adhesive.

In 2005, Charlene completed her wellness degrees in therapeutic aromatherapy and reflexology at the International School of Reflexology and Meridian Therapy. She worked for a company offering corporate wellness programs for several years before opening her own therapy practice. In 2015, she was asked by a digital marketer friend to join her company as a content creator, and it was here that she discovered her enthusiasm for writing. Since entering the world of content creation, she has gained a lot of experience over the years writing about various topics such as beauty, health, wellness, travel, crafting, and much more. Due to various circumstances, she had to give up her therapy practice and now works as a freelance writer. Since she is a very creative person and as a balance to writing likes to be active in various areas of art and crafts, the activity at acrylgiessen.com is perfect for her to contribute their knowledge and experience in various creative topics.

Learn more about Charlene Lewis and about us.