Epoxy Resin Guide – Most Complete Information Source for Resin

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

What is resin and what is the difference to epoxy and casting resin? Here you will learn the differences between the different resins, their areas of application and which are currently the best products on the market.

Table of Contents

- 1 What is Epoxy Resin?

- 2 What is Epoxy Resin or Synthetic Resin used for?

- 3 What you should pay attention to when buying Epoxy Resin

- 4 The right Epoxy Resin for your Project

- 5 Overview about the different Viscosities

- 6 Properties of Epoxy Resin at a glance

- 7 Are Synthetic Resins toxic or dangerous?

- 8 How can Epoxy Resin be colored decoratively?

- 9 Processing of Epoxy Resin

- 10 Answers to the most important Questions

- 10.1 Can Wood be easily sealed with Epoxy Resin?

- 10.2 How can Resin be removed from unwanted Areas?

- 10.3 What is Food Safe Epoxy?

- 10.4 What does Term Resin mean?

- 10.5 How can hardened Synthetic Resin be further processed?

- 10.6 Are Epoxy Resin Coatings waterproof?

- 10.7 What does Term Pot Life mean?

- 10.8 How to get Epoxy Resin Bubble-free?

- 10.9 What is the Difference between Epoxy Resin and Casting Resin?

- 10.10 How long does Curing of Casting Resin take?

- 10.11 How can Epoxy Resin be weighed as accurately as possible and mixed easily?

What is Epoxy Resin?

If you search the Internet for information on this topic, you will probably come across the terms epoxy resin, synthetic resin, cast resin, resin or epoxy resin again and again.

Resin or epoxy resin is a synthetic resin which can be used for many different purposes. The epoxy is created by mixing two components that are matched to each other. When the liquid resin is mixed with a suitable hardener, a chemical reaction is set in motion, which usually lasts several hours.

After mixing the components with each other, not only heat is radiated, but the material also changes from the liquid to the solid state. In order for the material to cure perfectly, the mixing ratio of resin to hardener is usually 1 to 1 or even 1 to 2.

Different epoxy or synthetic resins have different properties and can be used for many different applications according to the manufacturer’s specifications. There is a large number of different resins, which differ significantly in the duration of the curing process, hardness and insensitivity of the finished surfaces. Further properties for the selection of the appropriate epoxy resin can be factors such as heat resistance and the maximum layer thickness that can be applied to the material.

The different properties of epoxy resin in different product variants:

- Viscosity (flowability)

- Maximum thickness of the layer that can be applied per casting

- Duration of the curing process

- Adhesion properties on surfaces of different materials

- Degree of hardness after complete completion of the transformation

This guide is designed to help you understand what you should look out for when buying epoxy resin so that you have exactly the right material for your project.

What is Epoxy Resin or Synthetic Resin used for?

Epoxy resin is basically very versatile and can be used for various types of art and craft projects. Epoxy resin can be used for such things as the following:

- Soil sealing in living spaces

- Fixing of stone carpets indoors and outdoors

- Cut-resistant sealing of resin countertops in the kitchen

- Epoxy bar tops

- Stabilizing Wood with Resin

- Useful things made of epoxy resin and wood such as cutting boards

- Modern renovation ideas for old buildings

- Production of resin jewelry

- Quick repairs with special UV resin

- Epoxy resin art objects such as resin art paintings

- Casting of Epoxy molds and figures of all kinds

- Decoration objects such as Resin Geodes and Resin Petri Dishes

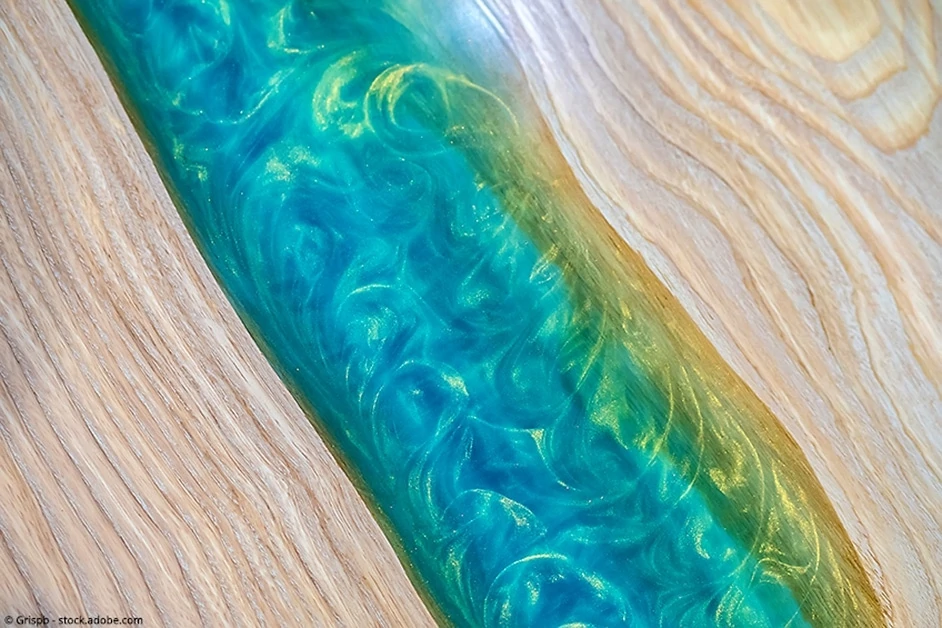

- Timeless furniture such as river tables made of epoxy resin

- Resin shelves for shower trays

- Waterproof Epoxy sealants for garage floors

- Resin casting of artifacts and materials in synthetic resin

- Self-construction of aquariums and terrariums

- Repairing and gluing small parts together

- Synthetic resin as topcoat or gelcoat for boat building

- Do-it-yourself construction of kiteboards

- Model building projects

What you should pay attention to when buying Epoxy Resin

You can now buy epoxy resin from many specialist dealers and in most DIY stores. If you order via the internet, the choice is even greater and you can often get the materials at a lower price. You will probably find by far the largest selection of high-quality products for all imaginable applications at many dealers online.

If you are just beginning to work with synthetic resins, you may be put off by the somewhat high prices of many synthetic resin components. Nevertheless, you should not look for the cheapest offers. There is a possibility that particularly cheap products are of inferior quality, which can also be seen in the result of your work and may demotivate you. In addition, some products may also contain solvents that are harmful to health or evaporate during the curing process. This can lead to the material not curing completely or being difficult to mix before. Some of the cheap epoxies also do not have a crystal clear transparency, but appear slightly yellowish during processing. This yellowish tinge can be intensified later by a little sunlight.

Tip: Even after a meaningful price comparison, you should buy the highest quality resin components possible, so that you can work well and achieve satisfactory results.

The right Epoxy Resin for your Project

In order to find the best epoxy resin for your project, it depends on the material properties that characterize a particular epoxy resin mixture. Based on the manufacturer’s specifications, you should be able to estimate how the resin can be processed and worked in both liquid and cured state.

Low Viscosity Epoxy Resins / Casting Resins

The term viscosity describes the flowability of liquids. However, caution should be exercised in this area: We speak of low viscosity when a liquid is particularly thin and free-flowing. So if you want to buy a low-viscosity casting resin, you should choose a low-viscosity epoxy resin. For some applications, an almost watery consistency can be very important: For example, if you want to cast molds or make river tables.

These low viscosity and very low viscosity epoxy resins cure very slowly. Therefore, you should plan longer intervals for the next steps of the processing. But you also have much more time for the processing and therefore no stress. Low-viscosity synthetic resin usually needs about 12 to 24 hours to cure. Because the exothermic chemical process of transformation is so slow, relatively little heat is released. Thus, in contrast to high or medium viscosity epoxy resins, you can easily process thicker layers and larger amounts of the resin in one step.

Absolutely recommendable, low viscosity casting resin:

- Custom formula causes minimal bubbles and avoids craters

- Epoxy when used and cured correctly it is safe with a low odor

- Mixes well with mica pigment powders and cures crystal clear

Possible applications for casting resin:

- Casting of all kinds of molds

- Manufacture of epoxy resin jewelry

- Creation of molded parts in the field of model making

- Production of furniture such as epoxy resin tables and resin river tables

- Filling cracks and holes in wood with epoxy

- Production of epoxy resin floors in the living area or garage floors

Viscous (highly viscous) Epoxy Resins / Laminating Resins / Countertop Resins

The consistency of many more viscous and thus highly viscous or medium viscous synthetic resins is reminiscent of the tough consistency of honey. The various products in this category are often referred to in the trade as laminating resin or resin. They are particularly suitable for coating surfaces. However, they can also be used to realize projects in the field of resin art and resin geodes. For highly viscous epoxies you should definitely follow the manufacturer’s instructions regarding the maximum layer thickness of each step. In many cases a maximum layer thickness of one to two centimetres is required for trouble-free processing.

For applications which require a high or medium viscosity resin, we recommend the following product:

- Specifically designed for art projects, developed with professional artists

- Heat resistant, scratch resistant, food safe, maximum UV resistant, water resistant

- compatible with alcohol inks, acrylics, silicone oils, metallics, oil-based paint

- Extended working time, easy to clean

Possible applications for laminating resin:

- Resin art – casting of paintings with epoxy resin

- Deco objects like Resin Geoden and Resin Petri Dishes

- Finishing of paintings and works of art of all kinds

- Certain variants of epoxy resin jewelry

- Sealing of surfaces such as worktops or tables

Overview about the different Viscosities

Layer Thickness

Thicker layers can easily be cast with particularly low-viscosity epoxy resins, as this resin does not heat up as much during curing. If there are air bubbles in the still liquid epoxy resin layer, you can remove them by carefully removing them with a hairdryer or a suitable Bunsen burner.

However, you should not pour thicker resin (e.g. laminating resin) thicker than about one centimetre. Due to the highly viscous consistency, it is very difficult to cause air bubbles to rise and escape from the resin.

Tip: The most important information can usually be found in the manufacturer’s details on the product packaging. For most products, this information also tells you what total amount of material you can easily use in one operation.

Processing Time

The processing time (also known as pot life or open time) is an essential factor when working with epoxy resins. It indicates the time span within which the epoxy resin can be processed after mixing the resin with the hardener.

From a certain point on, the resin becomes thicker and tougher and should not be used any more (except in special cases). From then on, it can no longer be colored homogeneously and does not even itself out to a flat surface.

Short Processing Time

Pros

- When dyeing with these epoxy variants certain effects can be achieved

- Fast layer build-up, as several layers can be poured on top of each other in shorter intervals

Cons:

- More difficult venting situation leads to more bubble formation

- Under UV-irradiation yellow coloring is possible

Long Processing Time

Pros:

- You have enough time to mix different colors and to work on them in peace and quiet

- When layering several transparent layers on top of each other, the transitions between the layers are hardly visible

Cons:

- To cast several layers you need more individual materials (mixing cup, spatula)

Curing Time

In the case of synthetic resin, the curing time describes the period of time after which a state of complete hardness and insensitivity has been reached after the components have been mixed. In most cases, there is a direct correlation between curing time and processing time: If the processing time is short, the resin usually cures completely even after a comparatively short period of time.

How much do the various products differ in terms of processing time?

For products with a relatively short processing time of about 20 minutes to one hour, the curing time is about 24 hours. Products with a processing time of up to 12 hours allow more complicated processing and effects, but it also takes up to a week for the resin to cure completely.

Properties of Epoxy Resin at a glance

The production and sales volumes of synthetic resins have increased rapidly in recent years. One of the reasons for this significant increase is that more and more people are becoming aware of the incomparable properties of this extraordinary material.

Advantages of Resin

Many people who come into contact with epoxy resin for the first time ask themselves what it actually is. The best way to answer this question is to list the special properties of the resin. The properties presented below refer to the solid state after mixing and curing. It can take up to a week to reach this state, depending on the product and manufacturer. You can usually find exact details about the curing time on the packaging instructions of your components. Sometimes it looks as if the resin is already completely cured, but in many cases the chemical transformation takes much longer than expected.

The following positive properties apply to almost every product once the epoxy is fully cured:

- Very high abrasion resistance

- High material strength

- Impact resistant (does not shatter or splinter)

- Usually a low shrinkage during the conversion from liquid to solid

- density values of around 1.2 grams (per cubic centimetre)

- Good UV resistance with correspondingly high-quality products

- Good adhesion on almost all materials (for example also on wood)

- High heat deflection temperature

- Acts as an electrical insulator

- High resistance to acids

- With careful substrate preparation: hardly any cracking of the epoxy resin

- Good weathering resistance in outdoor areas

Tip: High quality epoxy resin is hardly or not at all inflammable in liquid state.

Almost absolute Durability

A surface made of high-quality synthetic resin, which is fully cured, is extremely durable and abrasion-resistant. The material can be subjected to very high mechanical loads without deforming. Furthermore, it is acid-resistant and is not susceptible to corrosion. Therefore, high-quality epoxy resin is also used as a cut-resistant coating for kitchen worktops.

Possible Disadvantages of using Epoxy Resin

Although the positive properties of epoxy resins outweigh their disadvantages, there are also certain negative aspects of this material:

- Epoxy resins are not completely resistant to acids in high concentrations

- In some people, the liquid raw material can cause allergies or skin rashes after skin contact

- Some products are not absolutely lightfast under UV light and may yellow

- Already cured epoxy is difficult to remove

Are Synthetic Resins toxic or dangerous?

The liquid resin and hardener contain substances that are better off not being applied directly to the skin. Direct skin contact can, as with many other substances, cause irritation of the skin or even allergic reactions. We recommend that you work with epoxy only in well-ventilated rooms. Furthermore, you should always protect your eyes with suitable protective goggles and preferably also wear a breathing mask with filter. It is important that you follow the manufacturer’s safety instructions on the packaging.

You should take the following precautions when working with epoxy resin:

- Wear protective goggles that completely enclose the eyes

- wear old clothes with long sleeves and legs (or a protective suit)

- Only carry out work in a well-ventilated room

- wear undamaged nitrile gloves

- Wearing a breathing mask with integrated filter

- do not fill the vessel completely to the brim when mixing the components, otherwise the mixture can easily run over the brim when mixing

If these basic rules are followed, no major problems or dangers should arise when processing epoxy resins.

How can Epoxy Resin be colored decoratively?

As a rule, epoxy resins are absolutely transparent and colorless. Therefore they are often used to cast objects or collectibles into it. Transparent epoxy resin is also often used for self-built aquariums or terrariums. There are many other applications for which you may want to color the resin.

Which Colors are suitable for coloring Epoxy Resins?

The following types of paint are basically suitable for coloring epoxy:

- powdered color pigments

- Alcoholic inks (inks)

- color concentrates in liquid form

- Airbrush colors

However, you should never use paints that contain water. The water contained in them could prevent the resin from hardening or cause other undesirable effects.

The purchase of high-quality products for coloring epoxy resin is worthwhile in any case, because only if the quality is adequate can it be assumed that the color will be convincing in the long term due to its light-fastness. It is particularly annoying if you notice the fading of your epoxy resin artwork after only a few weeks.

- This is the ResinTint complete set with all basic colors

- Also included: metallic & neon set contains 8 shimmering colors

- High-quality coloring agents for epoxy resin

- High quality alcohol-based transparent inks, uncludes 9-0-1/2-ounce bottles

- Suitable for alcohol ink technique and resin petri dishes

- Hemway has one of the largest ranges of pigment powder dyes

- You can simply mix this slowly into resin until the desired ratio is reached

- Colorfast and lightfast, so your works will still shine brilliantly even after a long time

As an alternative to coloring the epoxy resin mixture, you can also paint your works of art afterwards with a high-quality two-component car paint. However, this comparatively high effort is usually only carried out under the special requirements of building aquariums and terrariums.

Processing of Epoxy Resin

If you want to process epoxy resin, you will need other tools and accessories in addition to the resin and hardener. We have summarized the most important ones for you here. We have also linked the appropriate instructions for the individual processing steps.

Mixing smaller Quantities of Epoxy Resin

For art with epoxy resin or for applications with small amounts of resin, there are special cups with a measuring scale. It is also recommended to use spatulas with a straight edge.

Mixing larger Quantities of Epoxy Resin

If you want to mix more than one litre of resin and hardener at once, you should use a sufficiently large container in which you can mix the mass evenly for several minutes using a drill with a stirring attachment.

Drill Epoxy Resin

Drilling epoxy resin is not easy because the material is very hard. To get nice holes, it is important to choose the right drill.

Depending on the number of holes and the money available, you can choose between two materials:

- HSS: High-performance high-speed steel is a cost-effective variant for drilling holes in epoxy resin. However, the material becomes blunt after only a few drillings.

- HM: Tungsten carbide drills consist of about 90 % tungsten carbide and about 10 % cobalt. This makes them much harder and more temperature-resistant, but also somewhat more brittle. For regular use or for drilling several holes, tungsten carbide drills are therefore the far better choice.

Sanding Epoxy Resin

You can sand epoxy resin either wet or dry. Wet sanding is usually done by hand, as water can cause short circuits in electric sanders. You will need wet sandpaper and a hard rubber sanding block. The surface is then sanded finer and finer with circular movements from coarse to fine grain. In this way, even sharp edges such as those on tables made of epoxy resin can be broken.

Polishing Epoxy Resin

Depending on the shape, surface and resin used, the surface may appear slightly rough and matt after the resin has been applied. Polishing the surface helps to counteract this. For larger surfaces, it is best to use a polishing machine with a suitable polishing paste. With this you can polish the epoxy resin to a high-gloss surface within a short time and according to your taste.

For smaller objects such as resin jewelry or casting molds, you can use a drill with a drill stand, leaving both hands free. This gives you maximum control over the polishing process.

UV Resin Processing

UV Resin is a special resin that hardens on contact with UV light. Since in our latitudes the sun often shines too seldom and not strong enough, curing is best done with a UV lamp or UV torch. The processing of epoxy resin is therefore very easy and the UV resin is already cured after about one to two minutes.

- Cures crystal clear with high-gloss surface

- Once cured, it's a really hard surface with high yellowing resistance

- Curing within 1-2 Minutes with a UV light.

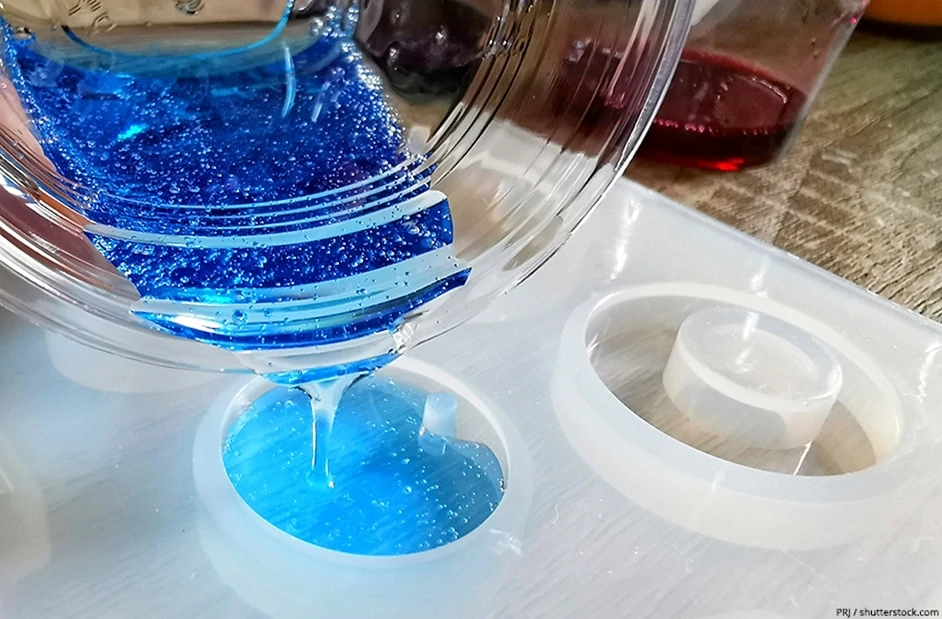

Pouring Epoxy Resin with Silicone Molds

Not only can you paint epoxy resin and use it as a coating resin, but you can also pour it into molds to create three-dimensional objects.

There are many possibilities from coasters and geometric shapes to more complex shapes and even jewelry. There is a wide range of different silicone molds, which are best suited for casting epoxy resin. After curing, you can simply put the non-adhesive silicone over the mold and mold the piece. If you want to make your own silicone molds, you can do this relatively easily with duplicating silicone.

Remove Epoxy Resin

If you ever need to remove epoxy resin, you will soon find that this is not so easy. When the casting resin has hardened, removal with a hot air dryer and a scraper has proven to be a good method. If the resin is still liquid, vinegar or isopropyl alcohol is suitable.

Answers to the most important Questions

In the following, we have summarized the answers to the most important questions about working with synthetic resin.

Can Wood be easily sealed with Epoxy Resin?

Various types of wood can be sealed very well with epoxy resins. This is even one of the main applications of synthetic resin. Epoxy can effectively seal the sometimes quite soft or even porous surfaces of wood and thus protect them from moisture. In this area, there are many applications of epoxy resins.

The following projects, among others, are possible:

- Repairs of boat parts with topcoat or gelcoat

- Sealing of table tops

- Sealing of wooden kitchen worktops

- Sealing all other wooden surfaces

You can also find more information on this specific topic in our guide text on wood epoxy.

How can Resin be removed from unwanted Areas?

The synthetic resin has particularly pronounced adhesive properties and is insensitive to mechanical loads of all kinds, which is a great advantage of the resin as a material. However, these properties also mean that it is particularly difficult to remove the epoxy after curing. Since the removal of the resin is so problematic without the help of other aids, we recommend that you use other means. With these you can re-liquefy the resin and then scrape it off the surface.

Wet the surface with the solvent acetone in a well-ventilated place and wait for about an hour. Afterwards the surface should already be slightly softened. Then you can heat the affected area with a heat gun up to a temperature of about 200°C. Once this temperature is reached, you will notice that the resin has liquefied again and you can scrape it off.

However, you should heat the area very slowly and carefully, otherwise other plastic or wooden parts may be damaged or burned. You can find detailed instructions and further information on this topic in our text on “Removing epoxy resin”.

Tip: When solid synthetic resin is liquefied with hot air, there is a possibility that harmful vapours are released. Wear a suitable breathing mask when working in this way!

What is Food Safe Epoxy?

Almost all resins are food safe after complete curing. However, with some synthetic resin mixtures, it can take several weeks until complete curing. Epoxy resins can be certified for use as containers for foodstuffs. However, most manufacturers refrain from doing so, as this is associated with high costs. If you would like to know more about this topic, check out our food safe resin guide.

What does Term Resin mean?

The term resin comes from English and originally meant resin in general. In the meantime, the term is often used with a special focus on epoxy resins. Especially in the field of contemporary art the term resin is often used when referring to resins. In most cases, resin is used as a synonym for epoxy resin in both English and German.

How can hardened Synthetic Resin be further processed?

When the epoxy resin is completely cured, you are basically holding a piece of hard plastic in your hands. Therefore you can rework the material in the following ways:

- Sanding (manually or with a machine)

- Drilling

- Polishing to high gloss (manually or with a polishing machine)

Are Epoxy Resin Coatings waterproof?

Epoxy resin is and remains waterproof after curing, provided it does not have any holes or cracks. This versatile material does not lose its waterproofness even in the long term over many years.

What does Term Pot Life mean?

The term pot life is sometimes used to indicate the maximum time span for processing the resin. The exact length of the pot life depends on the following parameters:

- Of the resin used and the manufacturer

- Of the amount of resin processed in one operation

- From the temperature values of the environment and workpiece surface

- From the temperature of the mixed epoxy resin

The consistency of the epoxy resin mixture changes in the course of the pot life from relatively thin to thick. At a certain point the resin mixture can no longer be processed and becomes solid. Depending on the amount processed and other factors, it may happen that only relatively little time remains after mixing the resin for processing. Therefore you should only mix as much as you can process without time pressure.

How to get Epoxy Resin Bubble-free?

- Avoid shaking the containers before mixing

- A steady hand during mixing prevents the increased undermixing of air bubbles

- it can be helpful if you preheat the resin and hardener in the container in a warm water bath before processing

- Some objects can sometimes release air bubbles into the resin during the casting process. This can be prevented by sealing these objects in advance with a thin layer of epoxy resin.

- In difficult cases you can also remove the air bubbles with a vacuum pump

What is the Difference between Epoxy Resin and Casting Resin?

Casting Resin:

- Relatively low viscosity

- Longer working time and also longer curing time

- The casting of thicker layers is possible in one operation

- ink layers mix faster with thinner consistency

Epoxy Resin / Laminating Resin / Tabletop Epoxy:

- More viscous than casting resin

- Significantly shorter curing time and therefore also rather short processing time

- Only relatively thin layers up to a maximum of 2 cm should be poured at once

- Different ink layers can be better distinguished from each other due to the viscous consistency

How long does Curing of Casting Resin take?

Some casting resins require a period of up to one week for complete curing. This long waiting time has advantages, however, as the processing time is correspondingly longer. With some epoxy resins, which can only be processed for a few minutes or for a maximum of one hour, stress can arise. When using resin casting resin you have much more possibilities with a processing time of up to 24 hours and therefore the following advantages:

- When working on larger areas, you can carefully position and embed objects for casting

- Larger quantities of resin can be colored with different colors in peace and without time pressure

- Due to the longer time span until curing, trapped air bubbles can escape more easily

How can Epoxy Resin be weighed as accurately as possible and mixed easily?

For an optimal mixing ratio of casting resin and hardener, we recommend the use of a digital scale. With some cast resin systems the perfect mixing ratio is also calculated by volume. You can measure this with a suitable measuring cup.

In 2005, Charlene completed her wellness degrees in therapeutic aromatherapy and reflexology at the International School of Reflexology and Meridian Therapy. She worked for a company offering corporate wellness programs for several years before opening her own therapy practice. In 2015, she was asked by a digital marketer friend to join her company as a content creator, and it was here that she discovered her enthusiasm for writing. Since entering the world of content creation, she has gained a lot of experience over the years writing about various topics such as beauty, health, wellness, travel, crafting, and much more. Due to various circumstances, she had to give up her therapy practice and now works as a freelance writer. Since she is a very creative person and as a balance to writing likes to be active in various areas of art and crafts, the activity at acrylgiessen.com is perfect for her to contribute their knowledge and experience in various creative topics.

Learn more about Charlene Lewis and about us.

![UV Resin – How to use UV Resin [Tutorial]](https://acrylgiessen.com/wp-content/uploads/2020/01/uv-resin-768x505.jpg)