Types of Resin – All About the Different Types of Epoxy Resin

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

There are so many uses for resin, it can be formed and molded into any structure or shape, it can be utilized as an epoxy, and can be camouflaged and blended as the substance it is adhering to or working in conjunction with. In this blogpost we give you an overview about the different types of epoxy resin.

Table of Contents

What are the Different Types of Resin?

There are a variety of different types of resin available, each with its own composition and properties. We will be giving a little insight into the following types of resin; UV Resin, Polyurethane Resin, Epoxy Resin, and Polyester Resin. Most resins are made up of two components, being the hardener (catalyst) and the base resin. When you mix together these components it causes a chemical reaction that enables the resin to set. UV resin is different in that it is only one component, as this type of resin requires exposure to UV light to trigger the chemical reaction and allow the resin to set.

UV Resin

As mentioned, UV resin is different to other resins, in that it is made up of only one component. UV resin sets very quickly, as it only requires exposure to UV light to activate the chemical reaction to that allows the resin to set.

- Features a quick-curing formula that hardens in minutes under a UV light

- This low-viscosity resin flows easily into molds and detailed designs

- The resin cures to a crystal clear, glossy finish, providing a professional and polished look

Application

To work with UV resin, you simply have to pour it over the item you have chosen to coat, you can color or tint the resin before you pour it, should you choose. To set the UV resin you will need to expose it to UV light. How long you need to expose it to the UV light is dependent on the thickness of the resin you have poured, and the size of the piece.

PROS

- You have a lot of time to work with this product, as it only begins to set when you choose to expose the resin to UV light

- This is the fastest drying resin available

- As there is only one component, there is no mixing required, decreasing the room for error

CONS

- UV resin can only be applied in thin layers, and therefore can not be used to cover large areas, due to this UV resin is only good for certain projects

- The shelf life is limited, being only 6 months

- It is quite an expensive product, in comparison to other types of resin

- To set the product you require a UV lamp, this is an expensive item

Polyurethane Resin

You can use polyurethane resin for casting molds, it is a very durable product that can be used to make a variety of items. Polyurethane resin is very durable and when set through applying heat, becomes very hard. There are a variety of different types of polyurethane resin that are used in several different industries, such as many appliances have polyurethane products in them, polyurethane is also found used often in the automotive industry.

- Protects indoor wood surfaces such as furniture, windows, cabinets, trim and more

- Water based formula dries fast and provides outstanding stain and scratch resistance

- Dries to the touch in 30 minutes with coverage up to 125 sq. ft., recoat after 2 hours

Application

The application process varies, depending on the reason you are using the polyurethane resin, an example is if you are making a mold casting with polyurethane resin you will need to combine the two components before you pour the resin into the mold. Another use for polyurethane resin is you can apply it to a surface to make the surface less slippery.

PROS

- This type of resin can be used as an electrical encapsulate

- Once the Polyurethane resin has been cured and set it is then heat resistant

- The polyurethane resin sets very quickly

- Polyurethane resin has great flow properties and can be easily mixed, these elements make it easy to fill a mold or any area

- There is hardly any shrinkage during the setting process

CONS

- Polyurethane resin isn’t as adhesive as the likes of epoxy resin

- Polyurethane resin is very sensitive to moisture, this can cause foaming

- Gives off an unpleasant odor when curing

- Once the resin has cured and set, you are not able to weld it

- You will need to add an additional additive to ensure polyurethane resin will not be impacted by UV light

Epoxy Resin

This is a very versatile form of resin, with so many uses, making it the go to resin for a great number of projects.

PROS

- Epoxy resin is a very durable type of resin

- the number of epoxy resins are very easy to customize and are all long lasting

- all epoxy resins are quite inexpensive and can be purchased with ease, of all the resins available, epoxy resin can be utilized for the greatest number of uses

CONS

- When exposed to direct sunlight, epoxy resin does tend to yellow

- Epoxy resin requires a dry atmosphere to dry sufficiently and set, therefore it is not ideal for use in high humidity environments

Application

How you go about applying epoxy resin, is all determined by what project you are doing. In short, in the basic application, one applies the resin layer by layer, allowing each layer to dry before applying the next layer. While you can sand down the resin once you have applied the initial coat, no more sanding should be done between any of the additional coats.

Coating Resin: Coating resin can be used to coat a surface or an item, and thereby creating a durable protective finish, which has a high gloss to it. Coating resin is ideal to coat the likes of concrete flooring.

- High-quality crystal clear Table Top Epoxy

- 100% Solid Material with no VOC and solvent additives

- When mixed using a 1:1 ratio

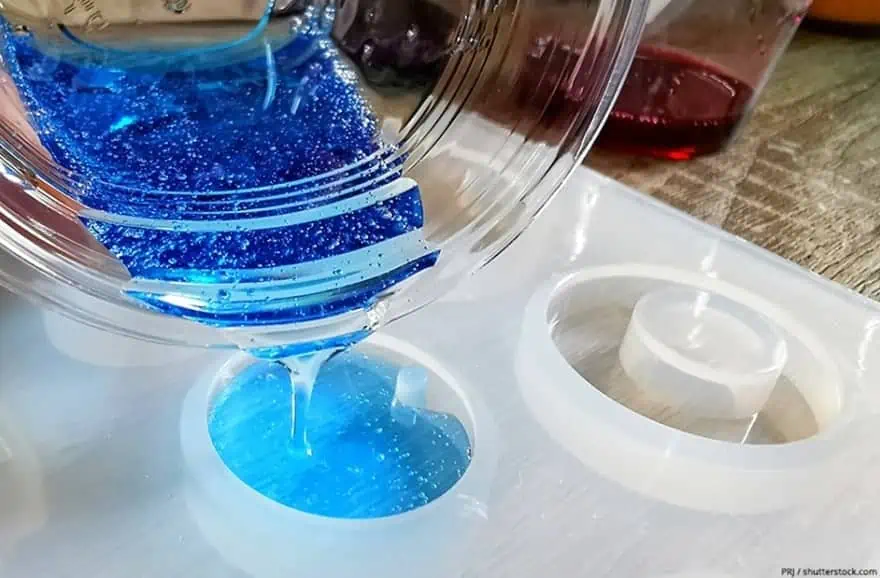

Casting Resin: Casting resin is a particular type of epoxy resin that has a low level of viscosity. Casting resin has a thin consistency which makes it a very useful type of epoxy resin, a negative to the thin consistency is that the casting resin takes longer to dry. Should you have a hollow void or area in wood or other materials, you can use casting resin to fill the space. An alternative use for casting resin is that you can completely submerge an item in it, allowing you to preserve the item.

- 2 : 1 mix ratio by volume (100 A to 44 B by weight)

- Thick pours up to 2" per application, low viscosity and long working time

- Super clear results, compatible with pigments and dyes

Polyester Resin

Similar to epoxy resin, polyester resin can be used to make models, it is most often used to make ponds, swimming pools, and in the building of boats. The resin has a fiber structure and is a strong resin, which is also water-resistant.

- 1 Gallon Polyester Resin and 0.75 oz CSM Fiberglass Chopped Strand Mat

- High quality Polyester Resin for all repairs on a wide variety of materials

Application

Polyester resin requires you to combine the two components prior to using the resin, you will need to add the hardener to the resin. The amount of hardener that is added determines the curing time of the resin. Once you have combined the two components you need to mix them completely, ensuring that neither of the components settle at the bottom of the container. Once you have combined the components you can then use the resin to laminate or to make a mold. If you have chosen to make a mold, make sure you apply the coats in one direction, this will help you avoid creating any air bubbles as you apply the resin to the glass fiber.

PROS

- As advised polyester resin is water-resistant

- This resin is very affordable

- You can determine the drying time required, as the setting time is linked to the amount of hardener used when combining the resin components

CONS

- The mixing process is actually quite technical and can be more challenging than that of other resins, as it is up to you to calculate the required levels when combining the two components

- Polyester resin is known for giving off a very strong, unpleasant smell

If you are using this type of resin to laminate, you begin by applying the first layer of resin onto the surface and then layer on top a sheet of glass fiber, you can then apply another layer of resin. In doing so you make the glass fiber mat flexible, ensuring you can shape it easily.

Conclusion

Which type of resin you should use is completely linked to the project you have chosen to tackle, once you have decided on your project you can then identify which resin to use. As shown each resin has its own pros and cons, one of the greatest positives of resin is that it can blend in and become camouflaged as the substance that it is adhering to.

Take a look at our epoxy resin webstory here!

In 2005, Charlene completed her wellness degrees in therapeutic aromatherapy and reflexology at the International School of Reflexology and Meridian Therapy. She worked for a company offering corporate wellness programs for several years before opening her own therapy practice. In 2015, she was asked by a digital marketer friend to join her company as a content creator, and it was here that she discovered her enthusiasm for writing. Since entering the world of content creation, she has gained a lot of experience over the years writing about various topics such as beauty, health, wellness, travel, crafting, and much more. Due to various circumstances, she had to give up her therapy practice and now works as a freelance writer. Since she is a very creative person and as a balance to writing likes to be active in various areas of art and crafts, the activity at acrylgiessen.com is perfect for her to contribute their knowledge and experience in various creative topics.

Learn more about Charlene Lewis and about us.