Epoxy Mold Release – How to use Resin Mold Release Agents

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

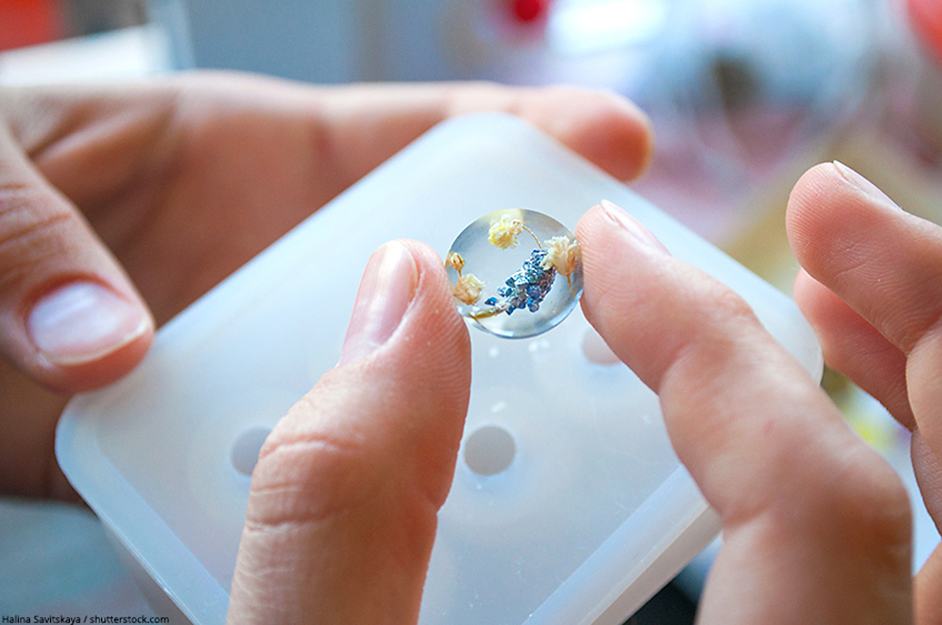

You can use your imagination when dealing with epoxy resin to create any shape you can think of. You can even make shapes and molds of your own, there is no limit to what you can do. The problem comes when you have to release your cured resin from the mold. For this, in many cases, you will need a resin mold release agent. Read on to find out more about the pros and cons of mold release agents and the various ways in which you can use them, especially for use on silicone molds.

Table of Contents

What are Mold Release Agents?

A mold release agent is a chemical that prevents certain materials from adhering to each other. Not adding a release agent will cause these materials to bond, which then produces more problems in cleaning up and creating a perfect casting.

Do you use epoxy resin and molds regularly? You will then understand the need for an epoxy release agent. Always use an epoxy release agent in your molds, as you do not want your epoxy resin to stick to your mold. Not only do you use the resin mold release agent on small castings, but on larger projects as well. For example, embedding epoxy resin into the wood, or other types of materials.

If you do decide to do your own molds, whether glass fiber mats or epoxy resin, remember to apply an appropriate mold release agent onto the negative mold form. However, if you do not use the release agent, the created mold won’t be able to come free, and all your work would have been for nothing. The epoxy release agent creates a barrier between the mold and the resin, preventing the resin from sticking to the mold. If the resin does stick, it will damage the mold, and more than likely you will not be able to use the mold again. Epoxy release agents can be used for:

- Polyester Resin

- Polyurethane Resin (occasionally)

When it comes to materials like wood, there is not a suitable epoxy release agent. This is because wood and some other materials like plaster or foam are porous, they will absorb the release agent and it will then be ineffective. So, in future, if we mention a wood epoxy release agent, it means that the wood has been sealed beforehand.

Mold Release Spray

When using an epoxy mold release agent, there are two forms of application, a release wax and release spray. Which one you select will depend on what you want to do. A mold release spray works well on more intricate and smaller molds because it is easily sprayed on. The wax release agent needs to be rubbed on to surfaces.

The mold release spray functions as a blend of wax substances and aerosol. The aerosol delivers the barrier wax substance onto the mold. The wax substance will remain while the aerosol particles evaporate.

Best use for Mold Release Spray

The mold release spray is excellent to use on molds that have detailed surfaces and lots of corners. The spray method can get into the corners and disperses the release agent evenly over an uneven surface. Sometimes, the release agent can remain on your resin casting. To get an even surface, you can polish your resin epoxy casting or try some soap and water. In most cases, this is not necessary.

Applying the Mold Release Spray

The surface you are going to spray must be clean and free from any greasy marks or dirt. The same is valid for all mold release agents including the wax and PVA release agent. If any residue is left on the surface of your mold before casting, it will stop the release agent from sticking to the mold. The release agent will simply glide over the surface without fulfilling its purpose. Once your casting has cured, it will demold with difficulty and this can damage the mold.

Once you have carefully cleaned the surface, shake your mold release spray can. Spray over your mold surface, making sure it is only a thin layer. Spray every angle and when spraying, make sure to hold the can about 20-30 cm away from the mold. Leave for about 2-3 minutes. Then, if needed, polish the layer with a soft cloth.

When it comes to new molds, you should apply at least three layers following the above process. Allow to flash off (the required time you need to wait before applying another coat) overnight after each layer has been sprayed.

We Recommend: Stoner Mold Release Spray

Stoner Molding has its own brand of mold release spray that also contains wax. You can easily use the spray on a variety of materials. The mold release spray makes demolding you’re casting an easy experience. The product offers all you could want in an epoxy release agent. Let us have a look at a few pros and cons when it comes to using the Stoner Mold Release Spray:

- Specifically formulated as a release agent and anti-stick lubricant

- Provides easy removal from molds for multiple mold processes

- Prolongs the life of your molds

Pros

- It is one of the epoxy mold release agents you can use on porous surfaces. So, this would be your choice for using on wood, but you should apply at least several layers to be effective.

- You can use it for both intricate as well as larger areas.

- Can be used for polyester resin, PMMA, polyurethane and casting resin.

- Free of silicone and any gases harmful to the environment.

- Effortless to use, even for beginners.

- Offers the best release effect and demolds flawlessly

Cons

- Not to be used for creating a barrier between silicone materials. If you want to separate silicone, a mold release wax or petroleum jelly is more appropriate for the job.

Mold Release Wax

The mold release wax comes in a container as wax and does not come in spray form. Most come in a liquid form, but others have a paste-like consistency. The wax can easily be applied with a brush or cloth. Put it directly from the container onto your cloth, which you can then use to rub onto your mold. You can also use the wax on other surfaces besides silicone. After you have applied the wax to your mold and after your resin project has cured, when removed, the surface may appear dull. You can easily remedy this by polishing it until it becomes shiny.

Best use for Mold Release Wax

The best way you can use release wax is on flat large surfaces. If you have a more detailed mold, it is better to use the mold release spray instead. Even if you use a cloth with the wax, it may be difficult to get into those small and difficult corners.

You can usually use a mold many times over, but it is advisable to clean the mold thoroughly after each use. You can easily clean your mold with some warm water and a bit of steel wool, this should remove any wax residue.

Applying the Mold Release Wax

When using a wax release, it is mostly in a liquid form, so shaking it before use is recommended. By doing this, the solvent and wax which can separate over time will mix again. Next, you can simply remove the wax with a spatula, then place it onto a clean soft cloth. Apply the wax to the mold with the cloth.

Leave the wax for about 5-minutes, you can then take another clean cloth to polish the wax. When it comes to new molds, you may have to apply another layer. You should leave the first layer overnight before applying the second layer.

To give the wax a more polished look, you can treat it with some PVA-release lacquer.

We Recommend: ORCA Shimmer Mold Release Wax

You can use the Orca Shimmer Mold Release Wax on all forms of resin, and it offers many benefits. Because of this, we highly recommend this product. When it comes to applying the wax release agent, it is important to note the flash-off time. When applying more than one layer of wax, you should wait overnight before applying the next layer. You should follow this rule as it prevents the wax from blending with the resin. When pouring your resin, the wax in your mold should not be sticky but smooth and tack-free. Let us have a look at a few pros and cons when it comes to using the Orca Shimmer Mold Release Wax:

- Highly effective carnauba-based paste wax for easy release

- Suitable for a wide range of different resin products

- Protects your molds and is resistant to abrasion

Pros

- The silicone mold release wax for resin can be used with a PVA release lacquer for a more polished effect. You do not have to add the PVA if you have properly polished the wax.

- The wax release agent is highly effective due to its consistency.

- The wax works not only well on epoxy resin, but also in polyester resin, topcoat, and Gelcoat resin.

- It is extremely easy to apply the wax and also to remove it.

Cons

- You cannot use the wax release agent on wood and other porous materials unless you first apply the proper release sealant or lacquer.

- The price of Orca Shimmer Mold Release Wax might be costly compared to other similar products, but the benefits are more than enough to offset this disadvantage.

PVA Release Lacquer

The Lacquer is used as a mold release agent, but also to help demold castings. Spray a layer onto your negative mold and is used in the same way as a release spray, creating a layer or film. The lacquer is made of polyvinyl alcohol and acts as an excellent mold release coating.

Best use for PVA Release Lacquer

To obtain the best results, in most cases the PVA release lacquer is used together with a wax release agent when used for epoxy resin. The lacquer acts as a second barrier between the resin and the mold.

This ensures that you have an easy and perfect demolding process and also provides a high-gloss surface. When using PVA-release lacquer you do not need to polish your cured resin item. Furthermore, you can use it on porous as well as sealed surfaces like wood, plaster, melamine, or resin press plates.

Applying PVA Release Lacquer

Applying the PVA epoxy release agent can be done in a variety of ways. You can use a brush or sponge, or you can use a spray gun. The best way to apply is to use a crossways motion. First, apply along the surface or up and down, then apply across or from left to right, and then again along end-to-end.

You should apply at least three layers, a thin first coat, which you should allow to dry or flash off for about 10-15 minutes. Then apply a thicker second and third layer, between each layer, you should wait 10-15 minutes for the lacquer to dry thoroughly before moving on.

Once you unmold your casting, you should be able to effortlessly remove any residue using a sponge and a bit of warm water.

We Recommend: PARTALL PVA Release Agent

This is a great product for silicone, wood, and many other materials. Let us have a look at a few pros and cons when it comes to using Partall PVA Release Agent.

- Forms a barrier between parts and mold surfaces

- It is resistant to solvents and styrene yet is water-soluble.

- Suitable for use with almost all types of resin

- Best product for producing high-gloss surfaces.

- You can easily blend it with a wax release agent for added benefits.

- An extremely concentrated product that is affordable.

- You can even use it with polyester resins, which demolds effortlessly.

- You can use it for epoxy and casting resin as well as for topcoat and gel coat resin.

There do not seem to be any real cons to the Partall PVA Release product, as it does what it says. The product is easy to use, with excellent demolding results. The product is the best mold release agent for all types of resin but is particularly good when used together with epoxy resin.

Substitutes you can use in place of commercial mold release agents

If you do not have a lot of money to splash on a special mold-release formula, or you only need to release one mold, there are a few DIY substitutes that you can use. You will find many of these substitutes in your home, and they are affordable and easy to use.

Petroleum Jelly

Petroleum jelly is best used on plain molds that do not have delicate details. You can easily apply a thin layer to your mold by hand. If you do apply it on more detailed molds, the jelly might cover up the finer details, which will then affect the final result.

Mineral or Vegetable Oil

Both these oils make a good mold release agent and can easily be applied with paper toweling. Be careful not to add too much oil, as it could pool. This can be remedied by using a paper towel, which will absorb any access oil.

Spray and Cook

Commonly used when cooking to keep food from sticking to a pan or other cookware. Easily available, spray and cook is a non-stick spray that is excellent to use as a mold release agent. The non-toxic spray will not damage your mold or the resin. Simply remove any residue from your final resin item with a clean cloth.

Talcum Powder

Talcum powder works great as a silicone mold release agent, but on molds that have fewer details. For example, a half-sphere mold or gem-shaped mold. Talcum powder does not work with solid or hard molds or molds with more details. This is because the powder does not cover the mold properly, so it won’t prevent the resin from sticking to these areas.

A Guide for effortless Demolding

When using epoxy resin, it depends on what mold you will be using to decide what mold release agent is best.

- Two-dimensional molds: a release wax works best.

- Detailed molds: mold release spray works best.

To effortlessly release your casting from the mold, you will need to take note of the following. It is all subject to the size of your mold and its design. When demolding, first try to work the edges loose. This should start the demolding process in most cases, some castings even come out straight away when turned upside down.

If your first attempt does not work, you can then try some demolding wedges. You can easily purchase these at your local hardware store or online. The wedges are also perfect for undoing two-part molds. You can also tap the mold softly with a rubber mallet to help dislodge your item from the mold. Another method to help with demolding if you have the equipment is to use compressed air.

If you are a common user of epoxy resin, for crafts or work, then at some point you will need a mold release product. In this article, we have described our top recommended mold release products and given you our tips and tricks for smooth releases. If you have any further questions, check out our frequently asked questions below!

Frequently Asked Questions

Can You Explain What Mold Release Wax Is?

Mold release wax is a substance used to avoid the binding of resin or other molding materials to a mold. Best to use on larger, flat casting molds, which form a layer between your mold and your casting agent. This prevents your casting from sticking to the mold.

Can You Explain What Release Spray Is?

Mold release spray is a substance that stops items from sticking to surfaces or to each other. The spray forms a layer or barrier between the mold and casting agent, making demolding an effortless process.

Are There Alternative Mold Release Agents?

You can use common materials like vegetable oil, mineral oil, cooking spray or petroleum jelly. This is a much cheaper way than commercial mold release agents.

Can the WD-40 Lubricant Act as a Mold Release Agent?

This product is made out of potent acids, which can seep into rust. Although the lubricant will only dry out your skin if exposed, it will certainly damage your mold. Also, it has an extremely thin consistency and won’t stick to the mold surface.

In 2005, Charlene completed her wellness degrees in therapeutic aromatherapy and reflexology at the International School of Reflexology and Meridian Therapy. She worked for a company offering corporate wellness programs for several years before opening her own therapy practice. In 2015, she was asked by a digital marketer friend to join her company as a content creator, and it was here that she discovered her enthusiasm for writing. Since entering the world of content creation, she has gained a lot of experience over the years writing about various topics such as beauty, health, wellness, travel, crafting, and much more. Due to various circumstances, she had to give up her therapy practice and now works as a freelance writer. Since she is a very creative person and as a balance to writing likes to be active in various areas of art and crafts, the activity at acrylgiessen.com is perfect for her to contribute their knowledge and experience in various creative topics.

Learn more about Charlene Lewis and about us.